CNC, stands for “Computer Numerical Control”, which is a high precision machine used for custom metal fabrication in order to make computer-controlled repeated movements. The concept is based on meticulous accuracy using computer-generated codes that are then converted to electrical signals, which in turn direct the CNC motors to make specific moves in small increments that are highly precise and repetitive.

Expensive yet highly versatile, CNC machines can be customised to make pretty much anything they are asked to do, which make them a great asset in the custom manufacturing industry to create parts. In the manufacturing industry, CNC machines can be a mill, lathe, router, welder, water jet cutter, laser cutter, grinder, sheet metal stamper or a robot for an assembly line.

Ogis Engineering has been a leading custom metal fabricator for over 50 years, and as we’ve seen the benefits of CNC machinery, we have invested in the latest CNC machines and advanced technology to stay on top of the metal fabrication industry in Australia.

Benefits of CNC Machines:

1. Optimal Productivity

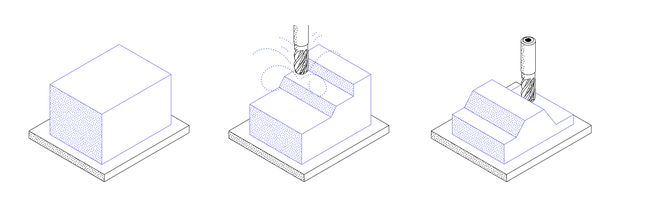

CNC machines are highly productive, using this subtractive manufacturing technology, parts are created by removing material from a solid block using a variety of cutting tools. As they don’t rely on manpower after setup, they provide greater productivity than other machines that depend on manpower to make them work.

2. Accuracy and Consistency

A very high level of manufacturing consistency and accuracy is achieved with CNC machines, as there is no human operator, which eliminates the probability for mistakes for personal reasons, such as being tired, distracted or in a bad mood. This means high quality custom metal fabrication with minimal waste.

3. Agile Technology

When using CNC machines, you can make design changes on-the-go as required, without the need of expensive tooling, which means you can provide advanced custom fabrication without charging your clients a fortune, as well as adjusting your designs as required, without the time expenditure in tooling setup.

4. Reduce Labour Costs

CNC machines save money on labour costs, which saves metal fabricators money allowing them to offer affordable custom metal parts, since the machine works on their own, not requiring skilled machinists for operators, only supervisors.

5. Adaptability

With CNC machines, no design is too complex, even curves. Check our recent curving gate design. In fact, CNC machines might be the only solution to accurately and consistently machine around compound curves while maintaining tolerance and extreme consistency.

6. Minimal Waste

CNC machines guarantee no or little waste material, as the parts can be machined consecutively.

If you would like to talk to a metal engineer about your custom metal fabrication project, talk to the experts at Ogis Engineering today.