Factors Influencing Metal Fabrication Companies

Metal fabrication companies play a crucial role in various industries, from construction to manufacturing. These facilities are responsible for transforming raw metal materials into intricate and functional products. However, there are several factors that contribute to their success and determine the quality of their output. Understanding these factors can give you valuable insights into the secrets behind metal fabrication companies and what you need to know. Let’s dive in!

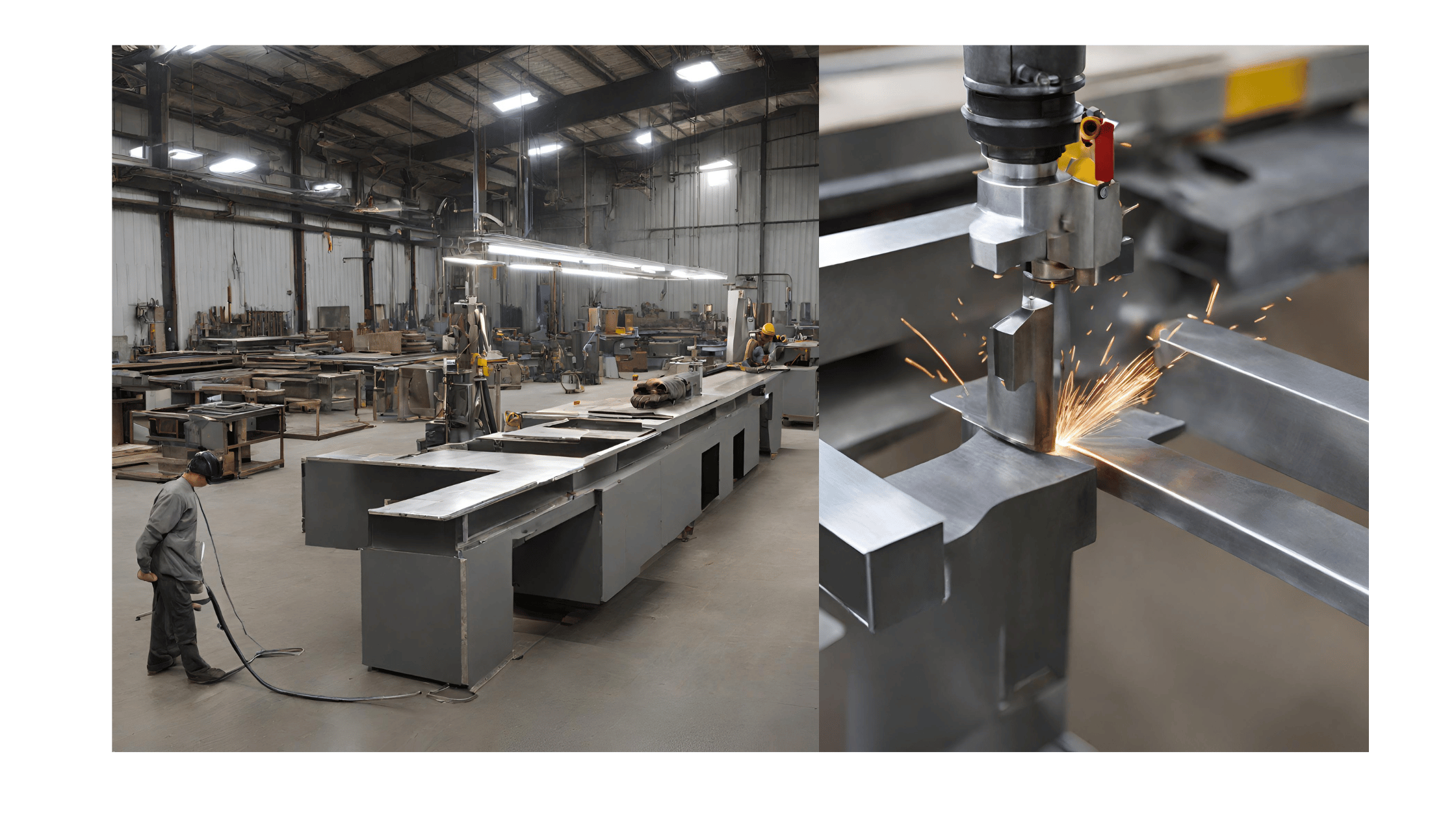

Importance of Equipment and Technology

When it comes to metal fabrication, the utilization of cutting-edge equipment and technology is paramount. Metal fabrication companies that invest in state-of-the-art machinery have a competitive edge over their counterparts. These advanced tools allow for higher precision, faster production times, and increased efficiency.

From computer numerical control (CNC) machines to laser cutters, the technology used in metal fabrication companies continues to advance at a rapid pace. CNC machines, for instance, enable precise shaping and cutting of metal components, ensuring consistency and accuracy. Additionally, laser cutters utilize laser beams to swiftly and accurately slice through various metals, eliminating the need for time-consuming manual labour.

By employing modern machinery, metal fabrication companies can produce complex and detailed designs with unparalleled precision. As a result, they can deliver products that meet the highest standards of quality and craftsmanship.

Fabrication Secrets behind: Skilled Workforce and Expertise

Behind every successful metal fabrication company is a skilled workforce with years of experience and expertise. These professionals possess a deep understanding of the intricacies of metal fabrication and are adept at working with different types of metals, such as steel, aluminium, and copper.

Welders, fabricators, engineers, and designers are just a few of the individuals who make up the backbone of a metal fabrication company. Their combined skills allow for the seamless execution of projects, from concept to completion. Each member of the team plays a vital role in ensuring the final product meets or exceeds client expectations.

Moreover, metal fabrication companies often invest in continuous training and development programs for their employees. This commitment to enhancing skills and knowledge enables the workforce to adapt to changing technologies and industry trends. With an experienced and well-trained team, metal fabrication companies can take on complex projects and deliver exceptional results.

Fabrication Secrets behind: Quality Control and Certifications

In the world of metal fabrication, quality control is of utmost importance to maintain industry standards and client satisfaction. Metal fabrication companies invest significant time and resources in implementing stringent quality control measures throughout their production processes.

Adhering to international quality standards, such as ISO 9001, ensures that metal fabrication companies consistently produce high-quality products. These certifications demonstrate their commitment to delivering excellence and meeting customer requirements. Additionally, quality control practices involve thorough inspections, testing, and documentation at each stage of the fabrication process.

One important aspect of quality control is inspecting the raw materials used in fabrication. Metal fabrication companies work closely with suppliers to ensure the materials meet specified standards. Additionally, they perform rigorous testing and analysis to verify the mechanical properties and composition of the metals.

By prioritizing quality control, metal fabrication companies can guarantee that every product leaving their facility meets the highest level of durability, functionality, and safety.

Conclusion

Metal fabrication companies are the backbone of various industries, and understanding the secrets behind their success is invaluable. By investing in cutting-edge equipment and technology, maintaining a skilled workforce, and implementing stringent quality control measures, these companies stand out in the competitive landscape.

As consumers, it’s essential to recognize these factors when evaluating and selecting a metal fabrication company. With this knowledge, you can make informed decisions and ensure that your projects are in capable hands. So, the next time you require metal fabrication services, remember the importance of equipment, expertise, and quality control – the secrets behind metal fabrication companies.

Ogis Australia can help you with further queries!!!