In the world of project management, especially within the fields of construction and manufacturing, accurate fabrication cost estimation isn’t just a benefit—it’s a necessity. The success of a project can hinge significantly on how well the costs were estimated before the work began. The aim of this article is to guide you through the complexities of fabrication cost estimation, offering insights into achieving precision, avoiding common pitfalls, and leveraging technology for the most accurate outcomes.

II.Understanding Fabrication Costs

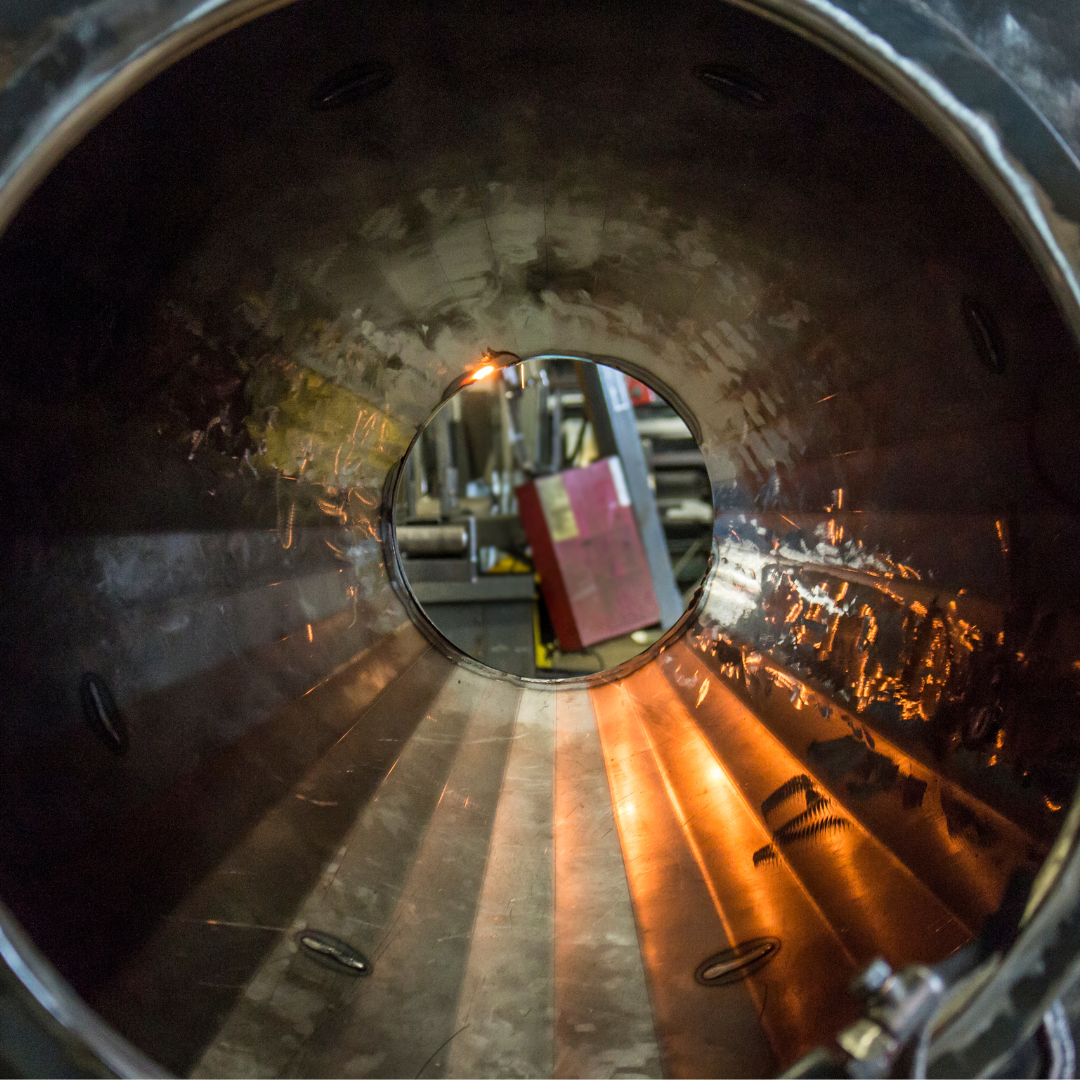

At its core, fabrication cost encompasses all expenses directly and indirectly related to the creation of a project’s physical components. This includes, but isn’t limited to, materials, labor, and overhead costs. Understanding these components is critical as they form the foundation upon which accurate estimations are built.

III. The Process of Fabrication Cost Estimation

The journey to an accurate fabrication cost estimate begins with gathering thorough information about the project. This might involve detailed drawings, specifications, and any other documentation that contributes to understanding the project’s scope. Today, various tools and software aid in estimation, offering precision and efficiency. However, don’t underestimate the value of professional consultation for complex projects.

IV. Factors Influencing Fabrication Cost

Numerous factors play into the ultimate cost of fabrication. The complexity of the project and the material selection are straightforward influencers, but one must also consider labor rates and geographical location, as these can significantly sway the final numbers.

V. Strategies to Achieve Accurate Cost Estimation

Achieving accuracy in cost estimation comes down to a few strategic approaches. Conducting a detailed project analysis is a no-brainer, but so is continual market research and networking with professionals. These strategies help you stay informed about material prices, labor rates, and the latest in cost-estimating technology.

VI. Common Pitfalls in Fabrication Cost Estimation

Common pitfalls often trip up even the experienced estimators, such as underestimating indirect costs or ignoring market fluctuations. Another frequent error is failing to account for potential project scope changes, which can lead to significant discrepancies between estimated and actual costs.

VII. Case Studies: Success and Failure

Examining both successful and underestimated projects can offer valuable insights. Success stories reinforce the strategies that work, while failed projects serve as cautionary tales, highlighting the consequences of inaccurate estimations.

VIII. The Role of Technology in Cost Estimation

Software solutions have revolutionized cost estimation, offering unprecedented precision and efficiency. Looking ahead, the role of AI in cost estimation seems promising, with potential to automate and further refine the estimation process.

IX. Tips for Beginners

For those new to fabrication cost estimation, start with a clear project scope and prioritize accuracy above all. Embrace each project as a learning opportunity, gathering as much experience and knowledge as possible.

X. Conclusion

Accurate fabrication cost estimation is critical for the success of any project. It requires a blend of detailed analysis, strategic planning, and an understanding of the factors at play. While challenges are inevitable, the strategies and insights shared here aim to empower you to navigate the complexities of cost estimation with confidence.

Contact us at Ogis Australia to help you with your cost estimate and complete your project with quality and precision.